Products

CX-L1400 BALER

Category: VFFS packing machine

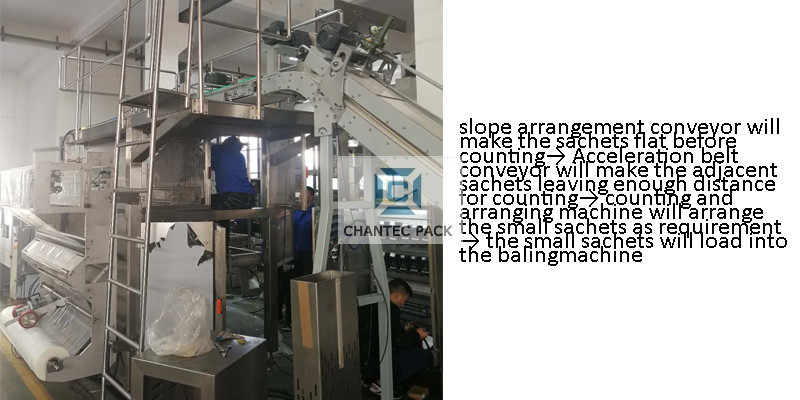

Production process:<br/> Horizontal conveyor belt for collecting the finished sachets → slope arrangement conveyor will make the sachets flat before counting → Acceleration belt conveyor will make the adjacent sachets leaving enough distance for counting → counting and arranging machine will arrange the small sachets as requirement → the small sachets will load into the CX-1100/CX-1650 bagging machine → bagging machine seal and cut the big bag → belt conveyor will take the big bag under the CX-1100/CX-1650 machine.

Product Detail

Product parameter

Designed for small sachets repack into PE bag, baling machine

Production process:

Horizontal conveyor belt for collecting the finished sachets → slope arrangement conveyor will make the sachets flat before counting → Acceleration belt conveyor will make the adjacent sachets leaving enough distance for counting → counting and arranging machine will arrange the small sachets as requirement → the small sachets will load into the CX-1100/CX-1650 bagging machine → bagging machine seal and cut the big bag → belt conveyor will take the big bag under the CX-1100/CX-1650 machine.

Technical Features:

| Bag type | Pillow type bag; |

| Speed | 4-6 bags/min |

| Bag Length maximum | 835cm |

| Bag Width maximum | 535cm |

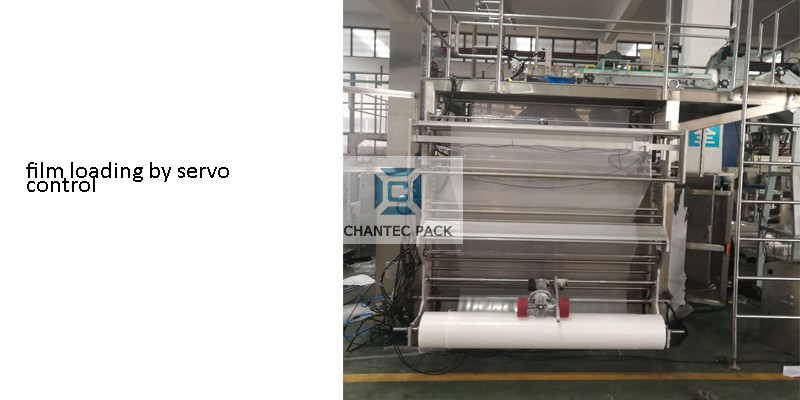

| Reel Film Width | ≤1100mm |

| Film thickness | 0.04-0.12mm (40-120mic.) |

| Reel Outer Dia. | 600mm (23.7in) |

| Reel Inner Dia. | 75mm (2.9in) |

| Voltage | AC220V/50Hz, 1phase or Per customer specification |

| Power Consumption | 4.5KW |

| Compressed Air Requirement | 0.6 Mpa 0.45 M3min |

| Machine Size | L2355 x W1735 x H2840mm; |

Pouch Drawings& Samples

Machine Details

Keywords:

Download attachmen:

Relative Products

sales@chantecpack.com

sales@chantecpack.com

+86 13731992050

+86 13731992050

Message

Message

Hotline: +86-0551-68899421

Hotline: +86-0551-68899421 Phone: +86 13731992050

Phone: +86 13731992050 Email: sales@chantecpack.com

Email: sales@chantecpack.com FACTORY ADD:2# workshop, no.200 chaoyang road,gangji town,changfeng county ,hefei,china

FACTORY ADD:2# workshop, no.200 chaoyang road,gangji town,changfeng county ,hefei,china