Products

CX-L1400 BALER

Category: VFFS packing machine

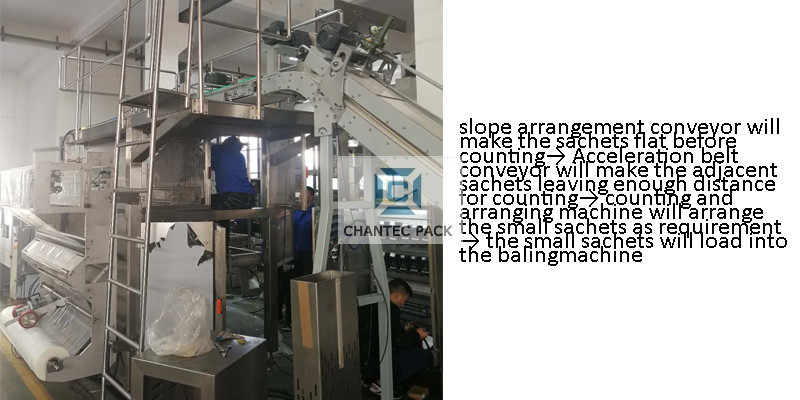

Production process:<br/> Horizontal conveyor belt for collecting the finished sachets → slope arrangement conveyor will make the sachets flat before counting → Acceleration belt conveyor will make the adjacent sachets leaving enough distance for counting → counting and arranging machine will arrange the small sachets as requirement → the small sachets will load into the CX-1100/CX-1650 bagging machine → bagging machine seal and cut the big bag → belt conveyor will take the big bag under the CX-1100/CX-1650 machine.

Product Detail

Product parameter

Designed for small sachets repack into PE bag, baling machine

Production process:

Horizontal conveyor belt for collecting the finished sachets → slope arrangement conveyor will make the sachets flat before counting → Acceleration belt conveyor will make the adjacent sachets leaving enough distance for counting → counting and arranging machine will arrange the small sachets as requirement → the small sachets will load into the CX-1100/CX-1650 bagging machine → bagging machine seal and cut the big bag → belt conveyor will take the big bag under the CX-1100/CX-1650 machine.

Technical Features:

| Bag type | Pillow type bag; |

| Speed | 4-6 bags/min |

| Bag Length maximum | 835cm |

| Bag Width maximum | 535cm |

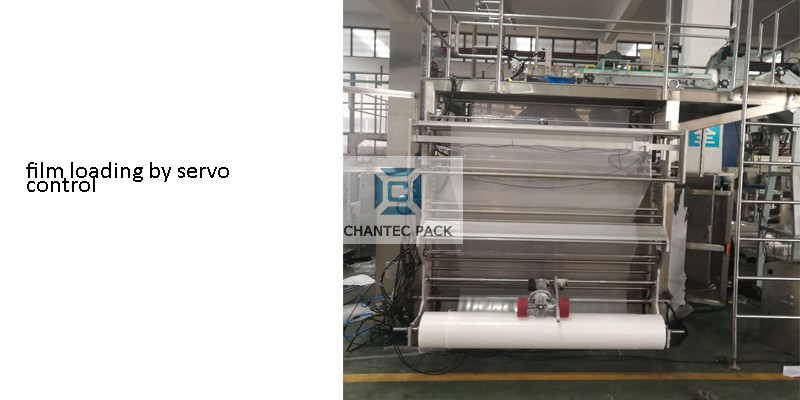

| Reel Film Width | ≤1100mm |

| Film thickness | 0.04-0.12mm (40-120mic.) |

| Reel Outer Dia. | 600mm (23.7in) |

| Reel Inner Dia. | 75mm (2.9in) |

| Voltage | AC220V/50Hz, 1phase or Per customer specification |

| Power Consumption | 4.5KW |

| Compressed Air Requirement | 0.6 Mpa 0.45 M3min |

| Machine Size | L2355 x W1735 x H2840mm; |

Pouch Drawings& Samples

Machine Details

Streamline your packaging operations with this efficient Bailing and bagging packaging machine from China. The CX-L1400 BALER system automatically collects, counts, and packages small sachets into larger PE bags at speeds of 4-6 bags per minute, creating a seamless workflow from individual items to finished retail packages. This integrated quality Bailing and bagging packaging machine features a sophisticated conveyor system that properly arranges sachets before counting and loading them into the bagging unit, ensuring accurate counts and professional-looking pillow-type bags every time. Production managers will appreciate how this equipment maintains consistent packaging quality while reducing labor requirements and minimizing errors in the packaging process.

The machine's robust construction ensures reliable performance in industrial environments, with the capability to handle various film thicknesses and bag dimensions according to production needs. This versatile Bailing and bagging packaging machine from China represents a practical solution for manufacturers seeking to automate their packaging line while maintaining control over package appearance and integrity. As a durable quality Bailing and bagging packaging machine, it offers the precision and reliability needed for continuous operation, helping businesses increase their packaging efficiency and maintain consistent output quality for their sachet products in competitive markets.

Keywords:

Download attachmen:

Relative Products

sales@chantecpack.com

sales@chantecpack.com

+86 13731992050

+86 13731992050

Message

Message

Hotline: +86-0551-68899421

Hotline: +86-0551-68899421 Phone: +86 13731992050

Phone: +86 13731992050 Email: sales@chantecpack.com

Email: sales@chantecpack.com FACTORY ADD:2# workshop, no.200 chaoyang road,gangji town,changfeng county ,hefei,china

FACTORY ADD:2# workshop, no.200 chaoyang road,gangji town,changfeng county ,hefei,china